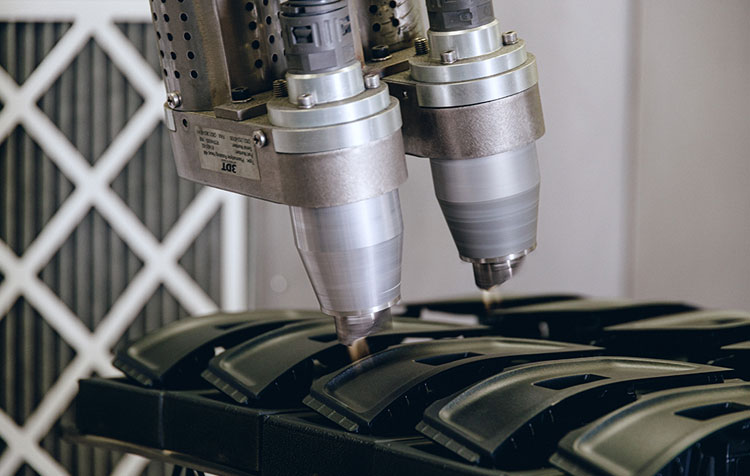

Somos expertos en la aplicación de múltiples tipos de acabados. Nuestras líneas de pintura están totalmente automatizadas en un diseño de múltiples cabinas. Todas nuestras cabinas de pintura están equipadas con sistemas de agua y robots de seis ejes, lo que nos permite procesar rápidamente una gran cantidad de piezas por hora en un ambiente limpio. Podemos pintar piezas con geometrías complejas y tenemos un control total sobre el grosor de la pintura, el brillo y el color de la pintura aplicada a sus piezas. Al final, nuestras excelentes líneas de pintura totalmente automatizadas le ofrecen piezas de la más alta calidad a un precio competitivo.

Dentro del proceso de pintura, una de nuestras principales ventajas competitivas está en la preparación y limpieza de las piezas, la cual se lleva a cabo en cuatro fases;

Limpieza manual

Aspiración mecánica

Limpieza con aire ionizado

Tratamiento con plasma

Después del proceso de limpieza, las piezas pasan a las cabinas de pintura, donde podemos aplicar hasta cuatro capas sin salir de la línea. Esto lo logramos mediante nuestro propio proceso de pintura “húmedo sobre húmedo”

La tecnología, digitalización y experiencia en nuestros sistemas de pintura nos permiten tener un control absoluto sobre los diferentes factores del proceso. Podemos lograr un acabado excepcional mediante el control automático del flujo de pinturas, mezclas, temperatura y humedad. La automatización de estos controles reduce el desperdicio de materiales y ayuda a obtener piezas terminadas en la primera pasada, mientras se mantiene un producto de calidad con la tasa de rechazo más baja de la industria.

Nuestros sistemas de 4 cabinas pueden aplicar hasta cuatro capas sin salir de la línea

Nuestro personal se distingue por su talento y experiencia. El título de “Paint Master” no es algo que se adquiere de la noche a la mañana; es un largo camino de ofrecer soluciones de calidad a nuestros clientes, como lo demuestra el reconocimiento de nuestra empresa por parte de Ford Motor Co. como socio, que utiliza nuestros procesos y tecnología dentro de sus sistemas estándar, también creados por nosotros.

Siempre a la vanguardia y en busca de nuevas tendencias, tenemos la capacidad de aplicar pinturas extremadamente complejas que nuestros clientes requieren y que nuestra competencia no puede comprender. Por ejemplo, somos líderes en la industria en aplicaciones de alto brillo, negro piano, tacto suave, brillo sedoso y cromo líquido.